Aspheric optics

2020-09-23

INTRODUCTION

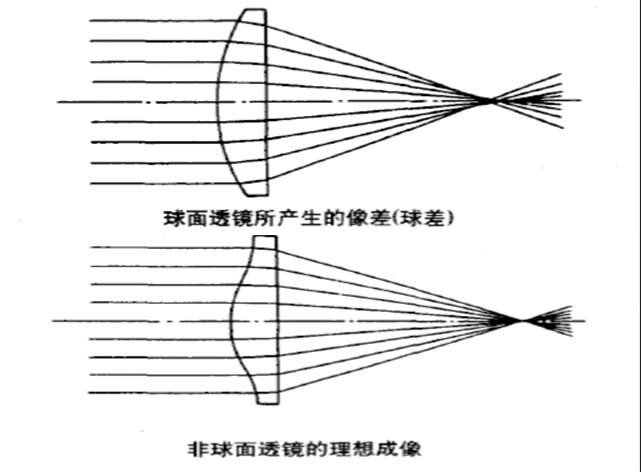

Spherical optical element refers to a constant curvature from the center to the edge of the element, and the surface is spherical; for aspheric optical elements, the curvature continuously changes from the center to the edge. Aspheric optical elements are widely used in aviation airborne equipment, satellites, laser guidance, infrared detection and other fields. At the same time, their applications in civilian optoelectronic products are becoming more and more popular.

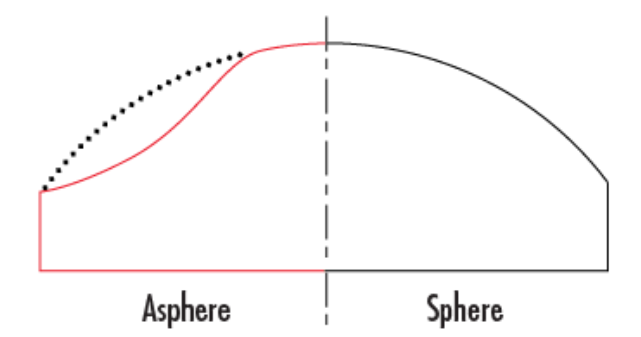

1. CLASSIFICATION of ASPHERIC SURFACES

2. ADVANTAGES OF ASPHERICAL SURFACE

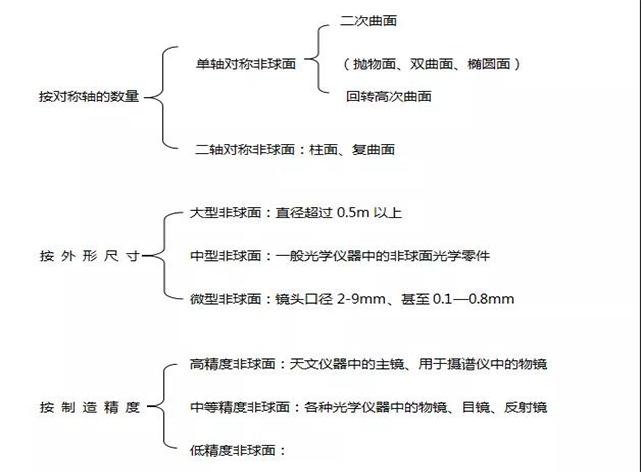

The following figure compares the focused spot produced by parallel monochromatic light passing through a spherical lens and an aspheric lens. The spherical lens causes the imaging point to be blurred due to spherical aberration, but the imaging point of the spherical lens is very clear. Therefore, aspheric lenses can be used to replace spherical lens groups to correct aberrations. For example, a lens with ten lenses can be used to replace five or six spherical lenses with one or two aspheric lenses to achieve the same or higher optical effect. To reduce production costs, and at the same time to achieve system lightweight and miniaturization. Moreover, an optical system that reduces the number of lenses will also reduce the system's mechanical tolerances, additional calibration steps, and antireflection coating requirements, improving the overall practicability of the system and reducing the overall system design cost.

The use of aspherical elements in the optical system can improve the performance of the system and reduce the number of optical elements, thereby reducing the weight of the instrument, reducing the volume and having a compact structure. Therefore, it is usually used in optical systems with large field of view, large aperture, high aberration requirements, small structural requirements or special requirements. Aspheric optical elements have increasingly become a very important class of optical elements due to their excellent optical properties.

3.THEMANUFACTURING PROCESS of ASPHERICAL SURFACE

The main processing methods currently used for aspheric optical components are:

1) Surface material removal method: CNC milling polishing method, ion beam polishing method, magnetorheological polishing method, liquid jet polishing method, etc.;

2) Method of changing material shape: glass hot pressing method, injection molding method, heat sinking and curing molding method, etc.;

3) Additional material method: vacuum coating copy molding method, hybrid molding method, etc.

Among them, ultra-precision numerical control milling and polishing are suitable for the occasion of producing a single aspheric lens at a time. With the improvement of manufacturing technology, its processing accuracy is getting higher and higher. The computer-controlled precision polishing technology can automatically adjust the tool residence parameters for precise polishing. Other manufacturing techniques generally require a special mold, and each lens has its own unique mold, but CNC milling and polishing use standard tools, so it can become the primary choice for prototype manufacturing and low-volume production applications.

4.FOCtek's ASPHERICAL

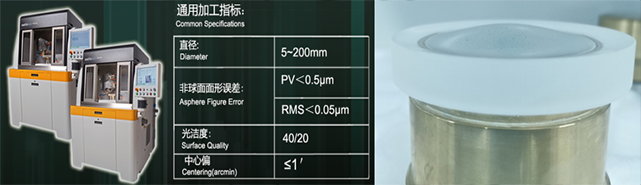

FOCtek's Ultra-precision aspheric surface milling and polishing equipment and aspheric surface general processing indicators.

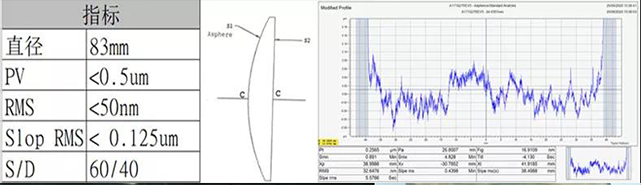

The first aspheric lens made from FOCtek.

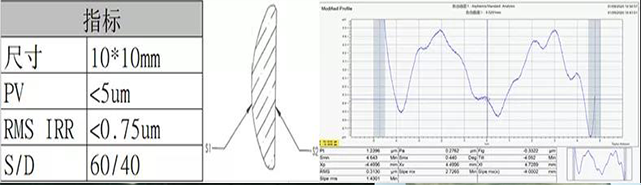

The first aspherical cylindrical lens made from FOCtek

Copyright © 2020 Foctek Photonics, Inc. All Rights Reserved All Rights Reserved 闽ICP备05011100号

Power:BAINANET

sales@foctek.com

sales@foctek.com